Singapore Polytechnic offers solutions to address the digitalisation needs of the local industry

22 Oct 2019

22 October 2019 – At the Industrial Transformation Asia-Pacific (ITAP) 2019 event today, Singapore Polytechnic (SP) unveiled a suite of innovations to help companies, including food manufacturers, stay relevant and productive in an increasingly digitised economy.

Currently many Small, Medium Enterprises (SMEs) which account for more than 90% of the industry, are often daunted by the cost and loss of revenue as a result of downtime when approached to replace legacy machines [1] with technologically advanced models. However, business owners are acutely aware of the need to digitalise to improve their business performance.

To address these concerns, SP is working closely with business owners to better understand their challenges. Innovative solutions have been developed to help SMEs move towards a digitised environment which can reap productive and performance benefits, and at the same time are economically sustainable.

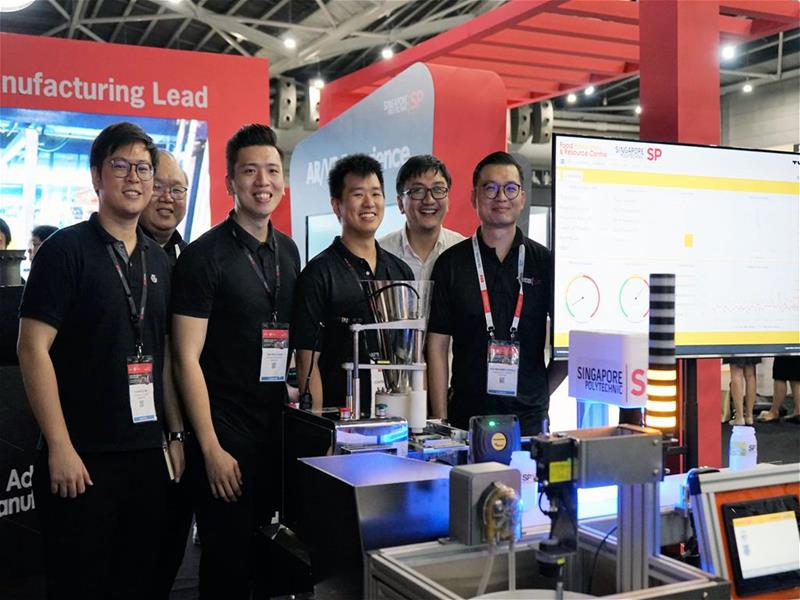

One innovation is a cost-effective solution to retrofit existing legacy machines for food and beverage SMEs with sensors and monitoring systems, using little or close to no downtime for retrofitting.

In collaboration with industry partners, SP's Food Innovation & Resource Centre (FIRC), developed a solution using systems and sensors to collect useful data that would allow food manufacturers to detect faults early, while speeding up and increasing the accuracy of food safety inspections. The systems are also able to monitor the performance of the machine, especially the integrity of moving parts that require frequent cleaning, and send out an alert for preventive maintenance.

“Simple improvements can go a long way in quality control and output. Over time, these steps will help companies lead to better and more reliable outcomes with significant cost savings. Singapore Polytechnic has invested significant resources in the area of helping companies move towards a digitalised environment. We are committed to helping companies create value in a financially viable way”, said Mr David Chai, Director for SP’s Department of Technology, Innovation and Enterprise.

Helping farms to automate

Another SP innovation featured at ITAP is a unique Smart Agriculture System to help vertical farms automate their processes.

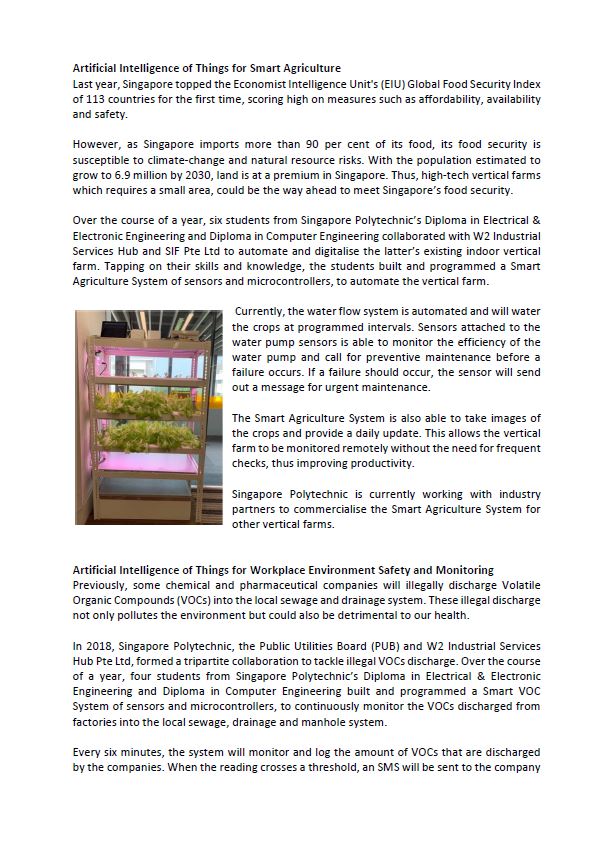

Over the course of a year, six students from Singapore Polytechnic’s Diploma in Electrical & Electronic Engineering and Diploma in Computer Engineering collaborated with W2 Industrial Services Hub and SIF Pte Ltd to automate and digitalise the latter’s existing indoor vertical farm. Tapping on their skills and knowledge, the students built and programmed a Smart Agriculture System of sensors and microcontrollers, to automate the vertical farm.

Currently, the water flow system is automated with sensors and crops are watered at programmed intervals. If a failure should occur, the sensor will send out a message for urgent maintenance. It is also able to monitor the efficiency of the water pump and call for preventive maintenance before a failure occurs.

The Smart Agriculture System is also able to take images of the crops and provide a daily update. This allows the vertical farm to be monitored remotely without the need for frequent checks, thus improving productivity. SP is currently working with industry partners to commercialise the Smart Agriculture System for other vertical farms.

Closer partnership with industry

At the ITAP 2019, SP will also be signing four memorandums of understanding (MoUs) with various industry partners:

- Bosch Rexroth Regional Training Centre

SP is partnering Bosch Rexroth, SkillsFuture Singapore and JTC Corporation in setting up the Bosch Rexroth Regional Training Centre (BRRTC) in the Jurong Innovation District. The MoU signing will also involve a few companies who have indicated commitment to work with BRRTC on Proof-of-Concept projects as well as sending their employees for training at BRRTC – particularly in the flagship AHK Industry 4.0 Specialist Certification programme which is developed based on German standards.

- A*STAR and SPETA

The MoU with A*Star and SPETA is to launch the Digital Ecosystem of Model Factories Initiative, where SP will be one of the participating organisation to provide an experiential learning experience at SP facilities including the Advanced Manufacturing Centre and Energy and Chemical Training Centre.

- Beckhoff

SP will partner Beckhoff to launch the SP-Industry Diploma Scholarship for Industry 4.0 talent development.

- OPC Hub Asean

SP will collaborate with OPC Hub Asean to set-up a first-of-its-kind OPC Application Centre in Singapore where SP students, local and regional companies will benefit with OPC Foundation certified trainings.

For more information on the solutions developed by SP across different industry sectors or details on the four MoUs, please refer to the factsheets.

Engineers from Singapore Polytechnic’s Food Innovation and Resource Centre with innovative solutions to retrofit existing legacy machines for food and beverage SMEs.

Lecturer and students from Singapore Polytechnic’s School of Electrical & Electronic Engineering collaborated with W2 Industrial Services Hub and SIF Pte Ltd to automate and digitalise an indoor vertical farm.

- End -

[1] Legacy machines are defined as those lacking digital capability to monitor operations or performance and are not part of the Internet of Things.

For more Information:

Mitch Teo

Lead Executive, Communications

T: 6590 2782

M: 9151 2232

E: mitch_teo@sp.edu.sg

About Singapore Polytechnic (www.sp.edu.sg)

Established in 1954, Singapore Polytechnic (SP) is Singapore’s first polytechnic. It has 10 schools that offer 40 full-time courses and three common entry programmes for close to 16,000 students. SP adopts a proven creative teaching and learning framework and offers students a holistic, authentic and industry-relevant curriculum, innovative and vibrant learning spaces, and enriching overseas programmes.

The Polytechnic is committed to producing competent and versatile graduates who are also imbued with sound values, so that they can be work ready, life ready and world-ready. SP has more than 206,000 graduates and among them are successful entrepreneurs, top executives in multi-national and public-listed corporations, and well-known professionals across various industries and leaders in government.

SP clinched the inaugural ASEAN People’s Award in 2015 for its contributions toward the region’s community-building efforts. SP is also the first polytechnic to be awarded the President’s Award for the Environment in 2010 and the President's Social Service Award in 2011.

SP clinched the inaugural ASEAN People’s Award in 2015 for its contributions toward the region’s community-building efforts. SP is also the first polytechnic to be awarded the President’s Award for the Environment in 2010 and the President's Social Service Award in 2011.

Follow SP on Facebook at http://www.facebook.com/singaporepolytechnic and Twitter and Instagram at @singaporepoly.